Hydraulic Press Brake Machine

Material | Mild Steel, Stainless Steel, GI and other metals |

Usage/Application | Sheet / Plate Bending |

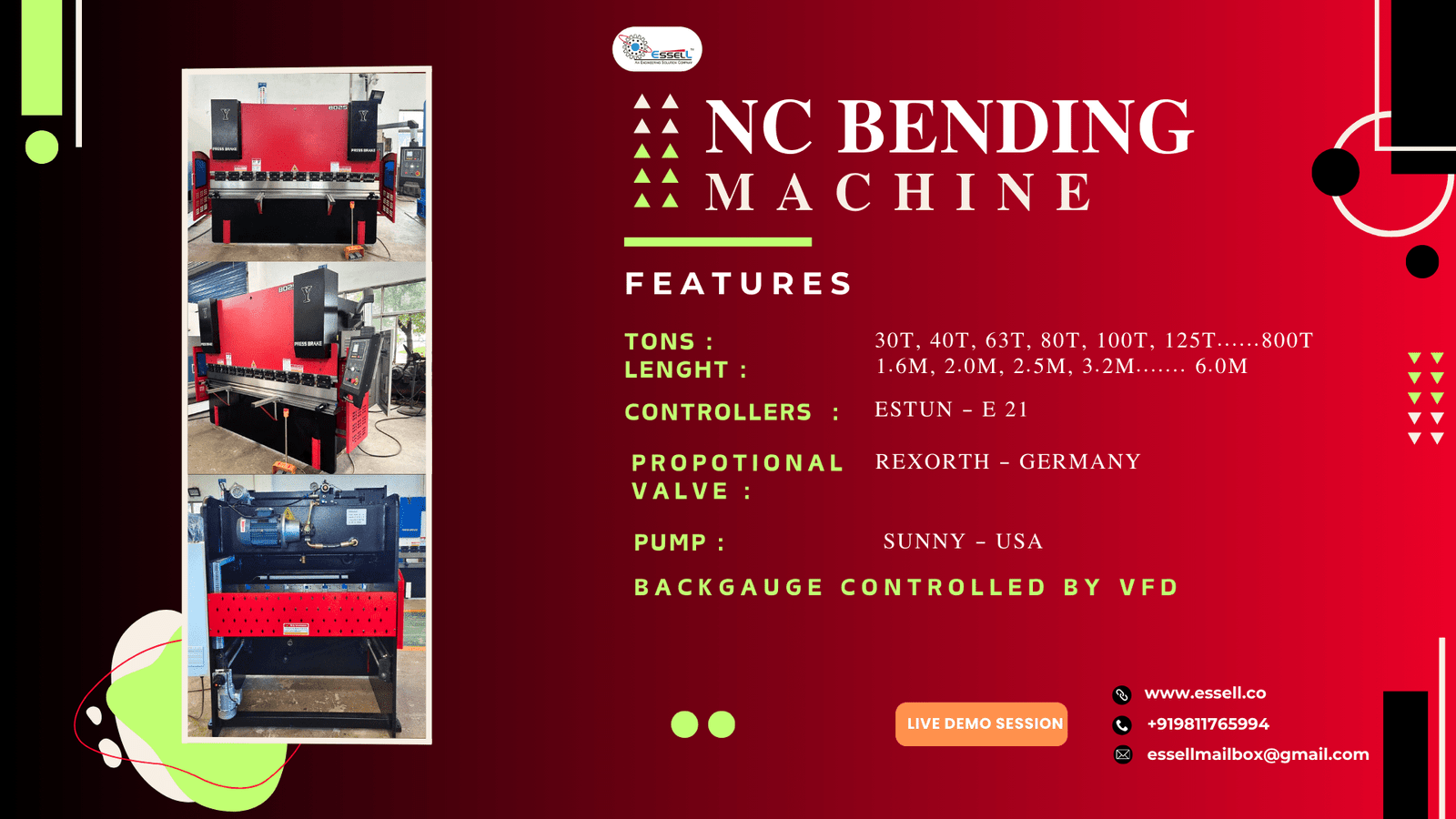

Control Axis | 2 plus 1 axis to…..7 plus 1 axis |

Max Sheet Width | 6 meter in single, more in Tandem |

Capacity | 30 – 1000 Ton |

Bending Material | Mild Steel, Stainless Steel, GI and other metals |

Max Force or Load | 30 T – 1000 T |

Voltage | 415 V, 50 Hz |

Control Type | NC / CNC |

Automation Grade | Semi -Automatics |

Frequency | 50 Hz |

Surface Finish | Powder Coated / Painted |

Max Sheet Width | From 1.5 m to 6 m |

Surface Finishing | Colour Coated |

Power | 3.5 hp to 25 hp |

Production Capacity | 100 pcs / month |

Delivery Time | 45 to 60 days |

- Product Type : Hydraulic Press Brake Machine

- Automatic Grade : Fully Automatic

- CNC Type : CNC

- Material : Metals Like MS, CS, Iron , SS, GI, Al, Cu, Brass

- Payment Terms : Standard via Cheque and Accommodating with Finance Facilities

- Supply Ability : 100 Piece Per Month

- Delivery Time 30-45 Days

- Sample Policy : Contact us for information regarding our sample policy

- Main Domestic Market : All India

Hydraulic Press Brake Machine

Frequent questions asked

Hydraulic Press Brake Machine is an essential equipment in metalworking, particularly for bending sheet and plate materials. It operates by exerting force through a hydraulic system, facilitating precise bending of workpieces between a die and punch assembly. This machine is highly valued for its versatility, as it accommodates various material thicknesses and bending angles with ease.

This machine is economical and very reliable solution for industry demand and are designed to give more accuracy and better productivity. The controller has a facility to program the various jobs with complex bending sequence on screen.

Key components of the Hydraulic Press Brake Machine include:

Hydraulic System: The heart of the machine, responsible for generating the force required for bending. It comprises hydraulic cylinders, pumps, valves, and reservoirs, ensuring smooth and controlled operation.

Bending Beam: The upper beam of the press brake that houses the punch. It moves vertically to apply pressure on the workpiece, resulting in the desired bend.

Bed or Bed Frame: The lower part of the machine where the die is mounted. It provides support for the workpiece during bending operations.

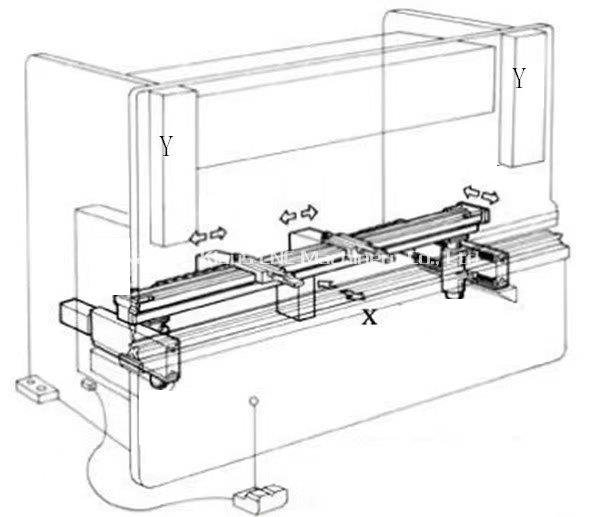

Back Gauge: A positioning device that assists in accurately placing the workpiece for consistent bends. It can be manually adjusted or controlled programmatically for automated setups.

Control System: Modern Hydraulic Press Brake Machines are equipped with advanced control systems, often featuring CNC (Computer Numerical Control) technology. These systems allow operators to program bending parameters, such as bend angle and length, and execute complex bending sequences with precision.

Revolutionize your metal fabrication process with our cutting-edge sheet and plate bending solutions. We specialize in bending a variety of materials including Mild Steel, Stainless Steel, GI, and other metals, catering to diverse industrial needs. Whether you require precision bends or high-capacity bending, our range of machines is designed to meet your specific requirements.

ESSELL hydraulic press brake machines feature advanced control systems, offering flexibility from 2 plus 1 axis, ensuring precise and efficient bending operations. With a maximum sheet width of 6 meters in a single bend, and even more in tandem setups, we enable you to tackle large-scale projects with ease and accuracy.

Choose from our extensive range of capacities, spanning from 30 tons to 1000 tons, providing the power and force necessary for bending various materials to your desired specifications. Whether you’re working with thin sheets or thick plates, our machines deliver consistent performance and exceptional results every time.

Operating at a voltage of 415V and 50Hz frequency, our machines are built to handle demanding industrial environments with reliability and efficiency. The control type options include NC or CNC, giving you the flexibility to choose the level of automation that suits your workflow.

Our hydraulic press brake machine are engineered for semi-automatic operation, combining the precision of automated systems with the versatility of manual control when needed. This automation grade ensures optimal productivity while allowing for manual adjustments and fine-tuning as required.

We understand in the world of globalization the customer has many choices and we appreciate your apprehension while looking towards ESSELL and wish to elaborate on why you should opt for ESSELL

- Efficient service support : ESSELL provides its customers dedicated & efficient services round the clock to ensure trouble free operations of machines. We have our service engineers stationed pan India at different Geographical locations to ensure commitment of 24*7 *365 service support.

Experience: With years of experience in the industry, we have established ourselves as a trusted provider of fiber laser solutions, serving a diverse range of industries and applications.

Customer Satisfaction: Your satisfaction is our top priority. We are committed to delivering cutting-edge technology, reliable service, and exceptional value to every client.

Continuous Innovation: We stay at the forefront of technological advancements, continuously investing in research and development to offer the latest advancements in fiber laser cutting technology.

Get in Touch

Ready to take your metal fabrication capabilities to the next level? Contact us today to learn more about our fiber laser services. Let us help you achieve superior results for your next project.

OUR PRODUCTS

Professional Fiber Laser Pipe Cutting Machine

Maximize Efficiency with the Latest Hydraulic Press Brake Machine From Essell

With more than ten years of expertise, ESSELL is a top provider of technical solutions with a focus on designing and building superior press brake machines. Our experience also includes manufacturing cutting-edge equipment, such as pipe cutting machines and laser sheet cutting machines with lasers. We are a reliable partner for companies looking for innovative manufacturing solutions because of our dedication to quality and innovation.

Top Benefits of Using a Hydraulic Press Brake Machine in Metalworking

- Press Brake Technology Expertise

We at ESSELL are aware of how important press brake machines are to the fabrication and shaping of metal. Our selection of press brake machines, which are designed to offer remarkable accuracy and dependability, comprises both manual and hydraulic press brake machines. The hydraulic press brake is perfect since it provides more power and control. We understand that purchasing machinery is a big choice for companies. For this reason, we provide press brake machine price that are competitive without sacrificing quality. With their long-lasting performance, our machines are built to provide you the most return on your investment. You can be sure that you're outfitting your workshop with equipment that satisfies the highest industry requirements when you deal with ESSELL.

- Superior Cutting Options

ESSELL is an expert in cutting-edge technologies in addition to press brakes. Our laser steel cutting machines greatly reduce waste and increase production efficiency by using strong lasers to produce accurate, clean cuts. The industrial industry has been further transformed by the introduction of automatic laser cutting machines. Higher throughput and automation in your operations are now possible thanks to the development of these machines, which have further transformed the manufacturing process. Because of their accuracy and adaptability, our laser sheet cutting machines can be used for a variety of tasks. Our machines are designed to dependably produce outstanding results, regardless of whether you are cutting intricate shapes or thin sheets. We give users easy control and programming choices by incorporating CNC machines into our cutting solutions, which improves the efficiency and usability of the cutting process.

Why Should You Choose Essell As Laser Welding Machine Manufacturer In Delhi?

Quality is the foundation of ESSELL. Every equipment we produce is put through a thorough testing process to make sure it satisfies our exacting quality control requirements. We are committed to provide dependable equipment that boosts output while reducing idle time. To keep our goods at the forefront of technology, our engineering staff is always coming up with new ideas. Furthermore, we think it's important to establish enduring bonds with our clients. Our committed support staff is available at all times to help with installation, upkeep, and troubleshooting. In order to maximize your investment, we provide thorough training programs to guarantee that your team can run our laser metal cutting machines efficiently.

Finally, when it comes to press machines and cutting solutions, ESSELL is your best bet. We offer a variety of goods, such as press brake machines, hydraulic press brake machines, laser sheet cutting machines, and pipe cutting machines, and we have over 10 years of experience in the field. We stand out in the engineering solutions market thanks to our dedication to quality, innovation, and client service. Get in touch with ESSELL right now to find out how our cutting-edge equipment can improve your production procedures and propel your company to success.